EnkiLife ELISA Kits

Providing scientists in the life science industry with efficient tools and excellent customer service, leveraging global supply chains and standardized processes to create a professional product matrix that meets diverse global needs.

Core Product Advantages

Raw Material Traceability Quality Control

From raw material selection to final product verification, all processes follow the ISO 9001 system, ensuring reliable quality and meeting global market access requirements. Each batch of products undergoes strict quality control processes.

1000+ Process Systems

Covering core methodologies such as sandwich, competitive, and indirect methods, perfectly matching various detection indicators and adapting to "annual production of 100,000-level" standardized production. Rich process accumulation ensures optimal solutions for different targets.

Flow Cytometry-Level Labeling Technology

Optimizing antigen-antibody binding kinetics, significantly improving detection sensitivity, easily identifying low-expression target molecules. Using flow cytometry-level labeling processes to ensure labeling efficiency and stability.

High-Sensitivity Detection System

Building a high-stability dilution system, amplifying detection signals, reducing blank noise, ensuring accurate and reproducible data in low concentration ranges. Proprietary signal amplification technology can reduce detection limits by 1-2 orders of magnitude.

Formula-Level Optimization

Optimizing buffer systems and stabilizer formulations for different target proteins to ensure long-term storage stability of kits without activity degradation.

Lyophilization Process Upgrade

Deeply optimized freeze-drying parameters, better product morphology, stronger activity after reconstitution, adapting to long-distance transportation and long-term storage needs.

Key Species Coverage

Core Research Area

High-Quality ELISA Kit Core Parameters

1 Sensitivity

Sensitivity is defined as "the lowest analyte concentration that can be significantly distinguished from blank noise," typically expressed as the detection limit (LOD = 3σ/a), where σ is the standard deviation of blank samples and a is the slope of the standard curve. The lower the detection limit, the stronger the kit's ability to detect target molecules in low-abundance samples.

EnkiLife achieves ultra-high sensitivity through multi-dimensional optimization:

- Using high-affinity monoclonal antibodies as detection antibodies to improve antigen-antibody binding efficiency;

- Optimizing labeling processes, using highly active molecules and improving labeling efficiency;

- Developing proprietary signal amplification systems that can amplify detection signals several times;

- Optimizing reaction buffer formulations to reduce non-specific binding and background noise.

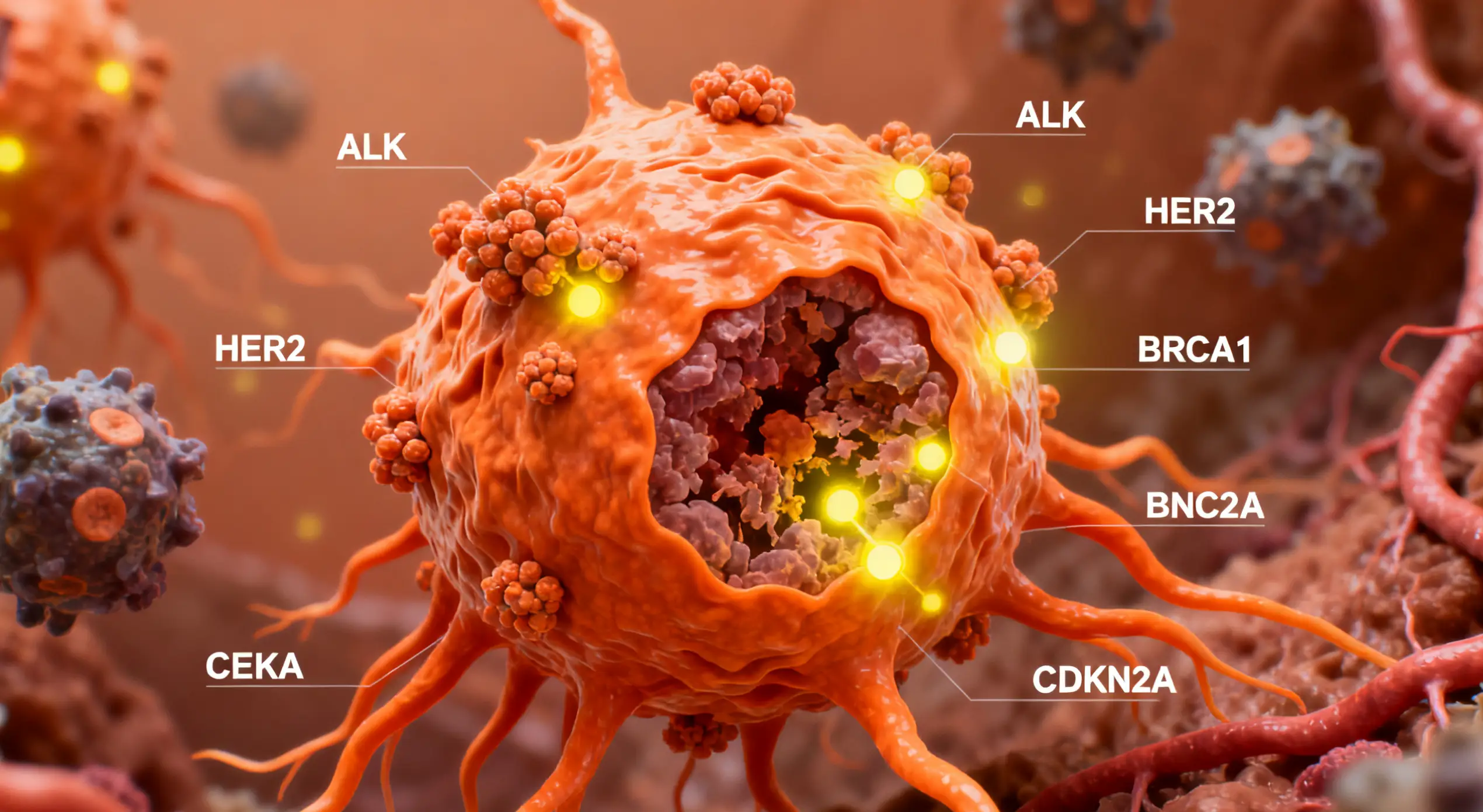

2 Specificity

Specificity refers to the ELISA system's ability to bind only to the target analyte without interference from structural analogs, homologous proteins, or matrix components. It is a core indicator for reducing false positives. Validation needs to cover same-family proteins, cross-species homologous proteins, serum high-abundance factors, and known interacting proteins.

EnkiLife ensures specificity through triple measures:

- Strictly selecting high-affinity, highly conserved epitope monoclonal antibodies to ensure precise antigen recognition;

- Systematically optimizing buffer systems to reduce matrix effects and non-specific adsorption;

- Using protein standards closer to natural conformations to avoid cross-binding caused by recombinant conformational changes.

3 Precision

Precision (CV) is a core indicator for evaluating the consistency of ELISA system detection results for the same sample under different batches, times, operators, and environmental conditions. Industry standards require both intra-batch and inter-batch CV to be below 10% to ensure data reliability and reproducibility.

EnkiLife ensures excellent precision through comprehensive quality control:

- Regular calibration of instruments: Equipment undergoes periodic metrological traceability, effectively eliminating systematic error sources;

- Fine control of process procedures: Using special process designs to eliminate time and space differences in production, avoiding edge effects and environmental fluctuations on results;

- High-standard consumable selection: Strictly selecting high-cleanliness, low-adsorption microplates and supporting consumables to reduce variation introduced by consumable batch differences;

- Systematic optimization of solution systems: Balancing stability and sensitivity to ensure consistent signal output under different conditions.

4 Recovery

Recovery refers to the percentage of measured concentration versus theoretical added amount after adding known amounts of target analyte to real sample matrices, used to evaluate matrix effects and accuracy, with an industry acceptable range of 80%-120%.

5 Linearity

Linearity refers to the proportional relationship between detection results and analyte concentration within the quantitative range of the kit. Validation method is "spiking standards in natural matrix and continuous gradient dilution," with industry requirements of 80%-120% recovery and R²≥0.99.

6 Stability

Stability uses accelerated thermal degradation model (37°C, 7 days) to simulate long-term storage, with criteria of key performance indicators CV<10% and activity retention ≥90%. EnkiLife ensures ≥12 months storage at 4°C through locked critical raw material batches and optimized buffer systems.

EnkiLife establishes a dual guarantee system:

- All critical raw materials come from validated batches, ensuring consistent physicochemical properties and biological activity;

- Optimizing buffer systems and stabilizer formulations for different target proteins, significantly reducing degradation rates at heat-sensitive sites.

Thus, the kit shows CV<10% under accelerated conditions with ≥90% activity retention, corresponding to ≥12 months real storage at 4°C, providing continuous and reliable performance assurance for long-term storage and transportation.